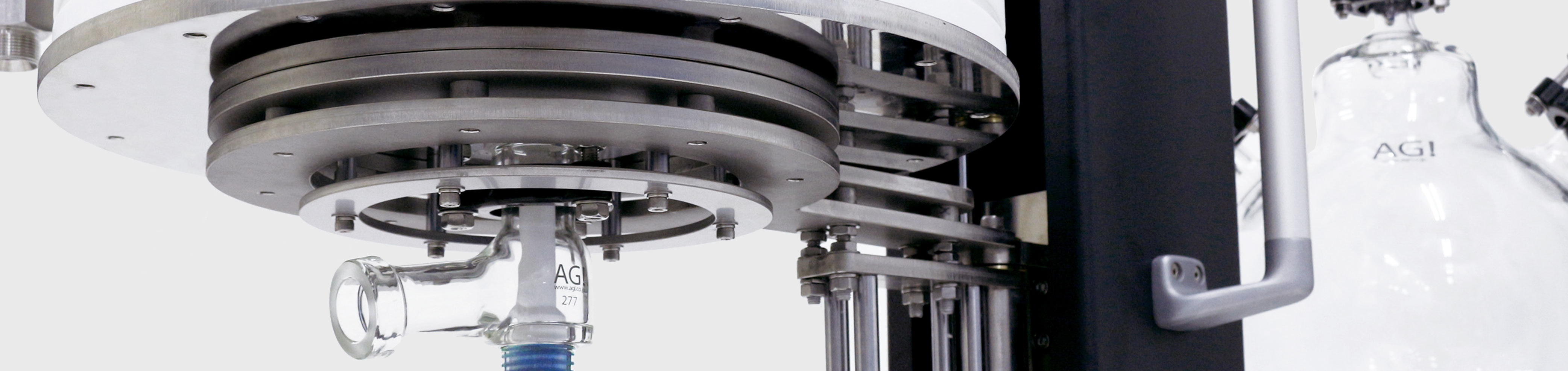

Pilot Plant Filter Reactor

AGI Pilot Plant Filter Reactor is designed to fulfil demanding crystallisation processes. Integrating the functionality of a reactor and a filter in one system, a full crystallisation process can be performed in the reactor without ever opening the vessel. Processes range from crystal formation, filtration, product washing and drying.

Large quantities of crystalline product can be processed easily and safely in the Pilot Plant Filter Reactor, making it ideal for process development, kilo lab and pilot scale production.

Reaction and Filtration in

a single vessel

Easy access to filter

using a lever mechanism

Design that safeguards against

product loss

Easy cleaning and maintenance

Scale-up up to 100 L

Wide process temperature range;

-90 ℃ to +200 ℃

Support structure with

castors for mobility

maximised thermal transfer efficiency

For an in-depth explanation of why AGI filtration systems are best for you, click here.

Functionality

General specifications

| Vessel capacity | 10 L, 20 L and 30 L |

| Vessel type | Double wall, full jacket |

| Filtration area | 317.3 cm² (10 L), 514.7 cm² (20 L), 711.6 cm² (30 L) |

| Operating pressure | Full vacuum to atmospheric pressure |

| Operating jacket pressure | Up to +0.5 barG (0.05 MPa) |

| Operating temperature | -90 °C to +200 °C |

| ΔT - Thermal shock resistance | 110 °C (double wall) |

Note:

Overhead stirrer, circulator and chiller are not included

Wetted parts: Borosilicate Glass 3.3, PTFE, FFKM, PFA

Customization possibilities

AGI Pilot Plant Filter Reactor can be customized and we are happy to discuss the design of custom features with you in order to meet your specific application requirements. Examples of custom work we've undertaken include the modification of lid accessories, vessel sizes, and creating a deeper filter base.

Pilot Reactor Controller

Unlock the power of your reactor with the AGI Glassplant Pilot Reactor Controller.

Something else in mind?

At AGI, we can help to find the best solution for you. If you have additional requirements or a design already in mind, feel free to send us a message and/or drawing so that we can understand your process better and provide you with a customised product that meets your exact needs.