Thin Film Evaporator

Wiper system

PTFE wiper blades spread the feed on the evaporation column to form a thin film. The grooves of the wiper blade are angled in such a way that, in addition to thin film formation over the evaporation surface area, it moves the film downwards with every rotation.

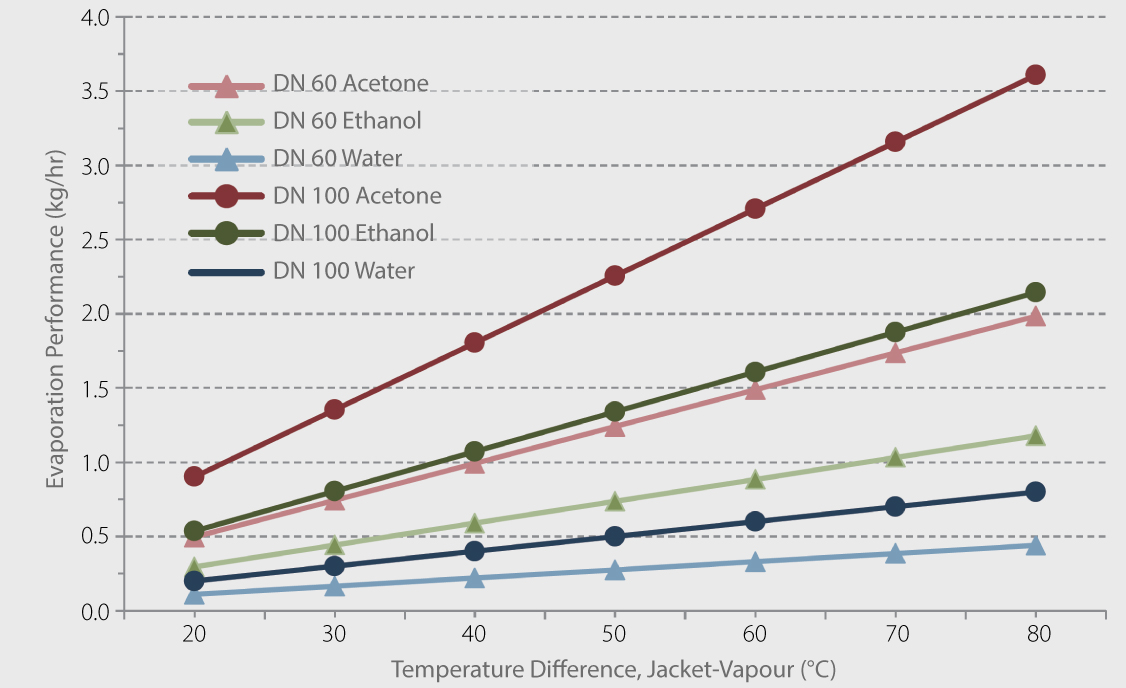

Evaporation performance

Different components evaporate at different rates in both thin film and short path evaporators. We studied the evaporation rates of different solvent types, which you can see in the graph on the right.

Experimental Conditions

* Pressure : Atmospheric pressure

* Flow rate of heat transfer fluid : 18 L/min

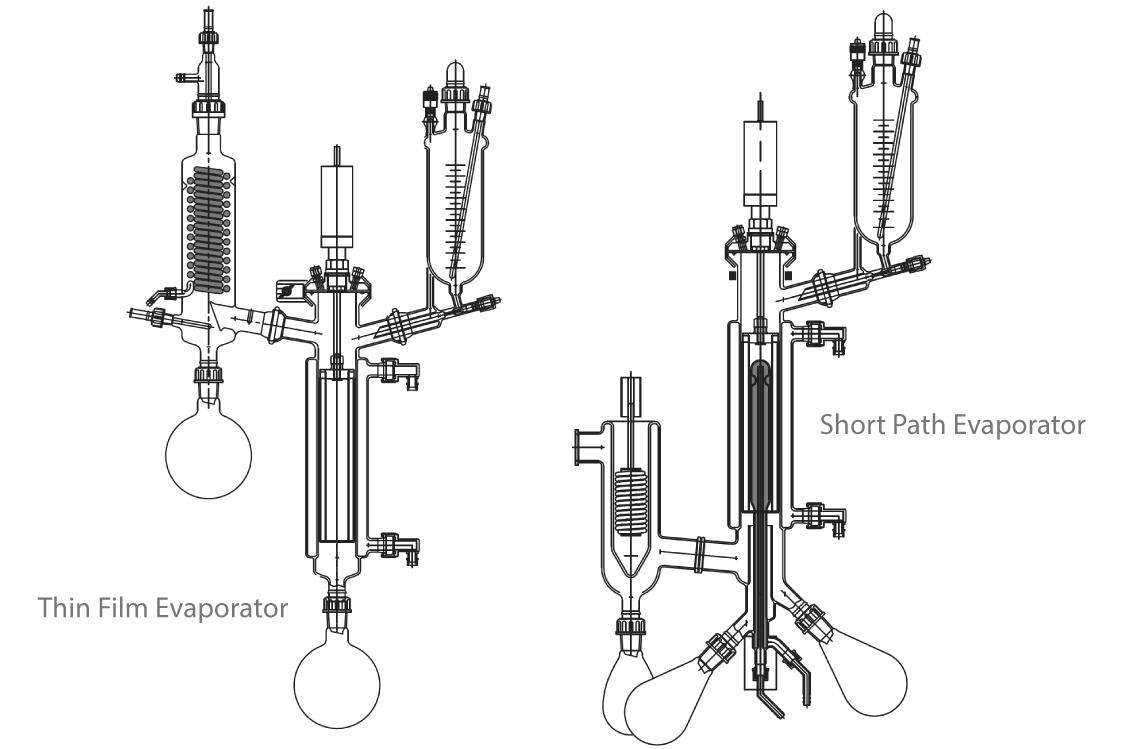

Difference between Thin Film and Short Path Evaporator

The main differences between AGI Thin Film and Short Path Evaporator are the operating pressure and the position of the condenser.

AGI Thin Film Evaporator has an external condenser and can operate from 0.1 mbar (abs.) to atmospheric pressure.

AGI Short Path Evaporator has an internal condenser co-axially positioned alongside the wiper and evaporation surface area. It can operate from 0.001 mbar (abs.) to atmospheric pressure.

The difference in pressure is due to the pressure drop that occurs when the vapour travels from the evaporating area to the condensing area. For our Short Path Evaporator, this distance is shorter compared to our Thin Film Evaporator. This means that AGI Short Path Evaporator can operate at very low pressure compared to AGI Thin Film Evaporator.

| Thin Film Evaporator | Short Path Evaporator | |

|---|---|---|

| Design Pressure | 0.1 mbar (abs.) | 0.001 mbar (abs.) |

| Condenser | External condenser | Internal condenser |

Easy installation and dismantling

AGI Thin Film Evaporator can be easily installed without the use of complex tools or steps. The rotary wiper can be easily removed for cleaning and reinstalled.

Easy to install and dismantle the rotary wiper

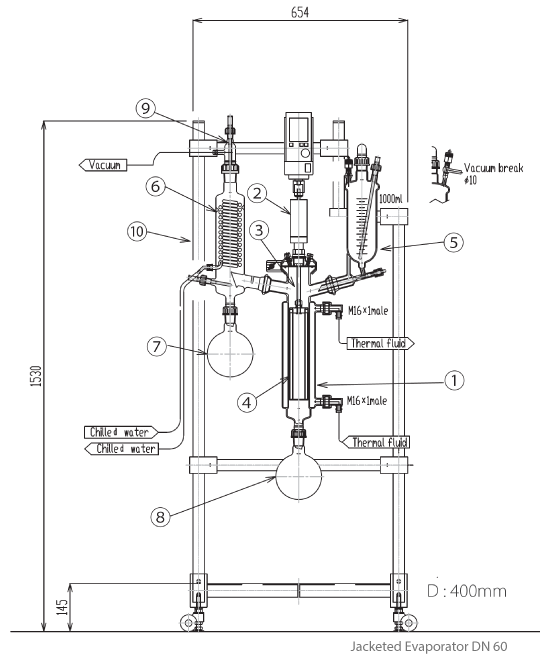

Standard package

| No. | Part | DN60 | DN100 |

| 1 | Jacketed Evaporator | ID 60 mm Evaporation Surface Area: 0.05 m2 | ID 100 mm Evaporation Surface Area: 0.1 m2 |

| 2 | Magnetic Seal with Cover | Torque: 1.1 N.m, Cover: SS316 | |

| 3 | Stirrer Shaft | SS316 | |

| 4 | Wiper | PTFE Wiper: +200 oC (Polybenzimidazole: +300 oC) | |

| 5 | Feed Vessel | Feed Vessel: 1000 mL Vent Valve: ф10 Thermometer Pocket SQG 14/25, ф8, 245(L) Cap SQG 29/32 Needle Valve, NGTV-12L | Feed Vessel: 2000 mL Vent Valve: ф10 Thermometer Pocket SQG 14/25, ф8, 330(L) Cap SQG 29/32 Needle Valve, NGTV-12L |

| 6 | External Condenser | Thermal Transfer Area: 0.1 m2 Thermometer Pocket: SQG 14/25, ф8 Water Connectors x 2: ф8 | Thermal Transfer Area: 0.2 m2 Thermometer Pocket: SQG 14/25, ф8 Water Connectors x 2: ф8 |

| 7 | Receiver for High Molecular Weight | 1000 mL Borosilicate glass 3.3 | 2000 mL Borosilicate glass 3.3 |

| 8 | Receiver for Low Molecular Weight | 1000 mL Borosilicate glass 3.3 | 2000 mL Borosilicate glass 3.3 |

| 9 | Adapter | Adapter: SQG 34/45, SQG 14/25 Ø 12 mm for vacuum connection Thermometer Pocket: SQG 14/25, 8 mm NW available as Option | |

| 10 | Structure | W 654 x D 400 x H 1530 mm SS + Epoxy Coating | |

Something else in mind?

At AGI, we can help to find the best solution for you. If you have additional requirements or a design already in mind, feel free to send us a message and/or drawing so that we can understand your process better and provide you with a customised product that meets your exact needs.